We support you in your project for your prototype foundry tools,

taking care to meet your expectations. We have the die casting

expertise to manufacture quality parts using our single or multi-cavity

steel moulds. These moulds will allow you to obtain tens to several

tens of thousands of parts in materials such as aluminium, magnesium or zinc.

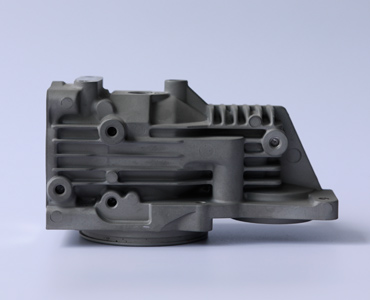

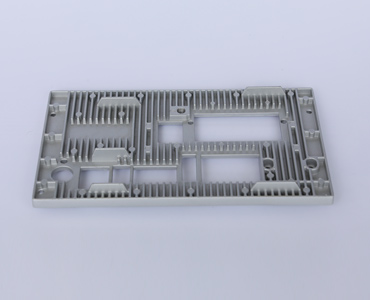

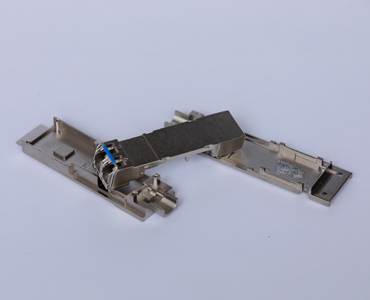

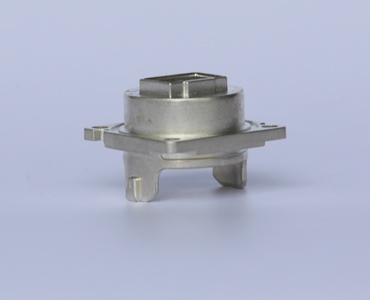

Die casting is a process of injecting metal under pressure into a steel mould to produce complex shaped parts with cavities. The precision of the dimensions eliminates some of the rework, which reduces machining and material costs. The most commonly used die casting alloys are aluminium, zinc and magnesium. This process combined with re-machining is generally used to manufacture complex parts with high precision.

Mold DFM analysis validation by the customer

Delivery of 5 to 20 sample parts for customer validation (T1 to Tn samples)

Injection of final parts following mold adjustment and validation of Tn samples

Aluminum

Zamak

Magnesium

Paints

Sandblasting

Treatments

Brushing

Cataphoresis

Polishing

Laser engraving