Silicone molding

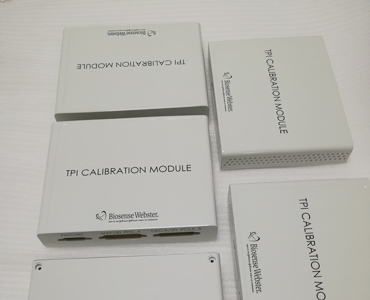

Prototypes & Preseries

Lead time: 7 to 10 working days (including transport)

Production from 5 to 100 units

Preseries of prototype parts can be made in polyurethane resin using vacuum molding in a silicone mold, based on a master machined in ABS,PA,POM, PMMA and PC.

Silicone material can be cast into a POM mold.

Several flexible, rigid, transparent and light-diffusing polyurethane resins

Possibility of overmolding and adding inserts

Standard: +/- 0.20 mm every 100 mm

5 vacuum casting machines

2 heat chambers

Paints:From a RAL or PANTONE reference, or a sample,

All kinds of finishing: Satin, glossy, matte, soft touch,

textured and chrome-style painting

Polishing:Smooth and shiny appearance (stereolithography)

Vacuum casting benefits to your low-volume production